The steps of the egg hatching machine operation management program are as follows:

(1) Preparation before hatching.

Before hatching, a reasonable hatching plan should be formulated according to one’s own hatching equipment, hatching capacity, egg source and sales capacity. The incubation room should maintain good environmental conditions.

The temperature should be 15~25℃, the relative humidity should be kept at 55%~60%, and good ventilation and light should be ensured.

A few days before the eggs are hatched, the hatching room and incubator should be thoroughly cleaned and disinfected, and the incubator should be carefully debugged and tested for 2 to 3 days, and can be used after everything is normal.

In order to improve the hatching rate, the eggs should be preheated and tested before hatching.

Generally, 12 to 18 hours before hatching, preheat the eggs at room temperature of 22 to 25 °C, and then perform fluoroscopy one by one after the eggs are placed on the plate to remove cracked eggs, broken eggs and foreign eggs.

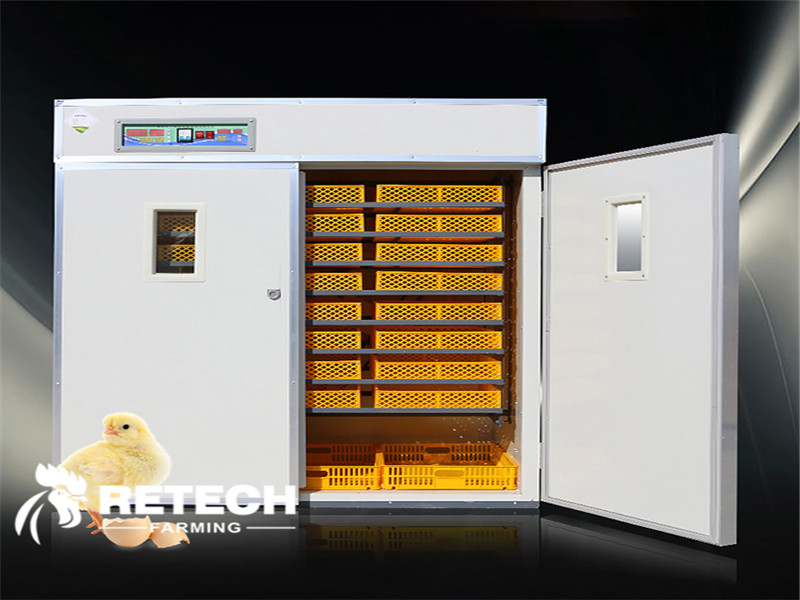

egg incubator

(2) On the egg.

When everything is ready, it’s time to serve the eggs. The egg laying time is generally carried out between 16:00 and 17:00 in the afternoon, so that the shell can be caught in the daytime.

If the eggs are not laid in a whole batch, the positions of each set of egg trays on the egg rack should be staggered during incubation to adjust the temperature of the new and old embryonic eggs.

Eggs are generally laid in batches every 3 to 5 days. An incubator with good ventilation and temperature regulation can be filled with eggs at one time.

(3) Management during incubation.

Temperature adjustment: During the incubation process, it is best to check the thermometer every 0.5 to 1 hour and record it every 2 hours. The temperature adjustment is generally based on the temperature of the door table.

Different egg laying systems have different temperature adjustment methods. If the “all-in and all-out system” is adopted, the whole batch is hatched, and variable temperature incubation can be used; if batches of human hatching are used in the machine, constant temperature incubation should be adopted.

Under normal circumstances, when the temperature inside the machine is 0.5 to 1°C of the specified temperature, it should be adjusted. In addition to the temperature index of the door table, the incubator should also adjust the temperature according to the temperature of the embryo, that is, adjust the temperature according to the speed of the embryo.

It is strictly forbidden to adjust the temperature suddenly high and low, so as not to cause poor embryonic development.

Humidity regulation: Check and record the hygrometer every 2 hours. For incubators that do not automatically adjust humidity, warm water should be added to the water tray regularly every day, and the number of water trays and the water temperature should be adjusted according to the humidity level to ensure suitable humidity.

Advanced incubators have automatic hygrometers, automatic alarms, and automatic adjustment of moisture evaporation. The automatic humidity control device should pay attention to check its sensitivity frequently.

Turning eggs: At present, machine hatching is mostly automatic egg turning. The general control is to turn the eggs once every 1 to 2 hours. Pay attention to whether the automatic egg turning is normal. If manual egg turning is implemented, it is best to turn the eggs once every 3 hours.

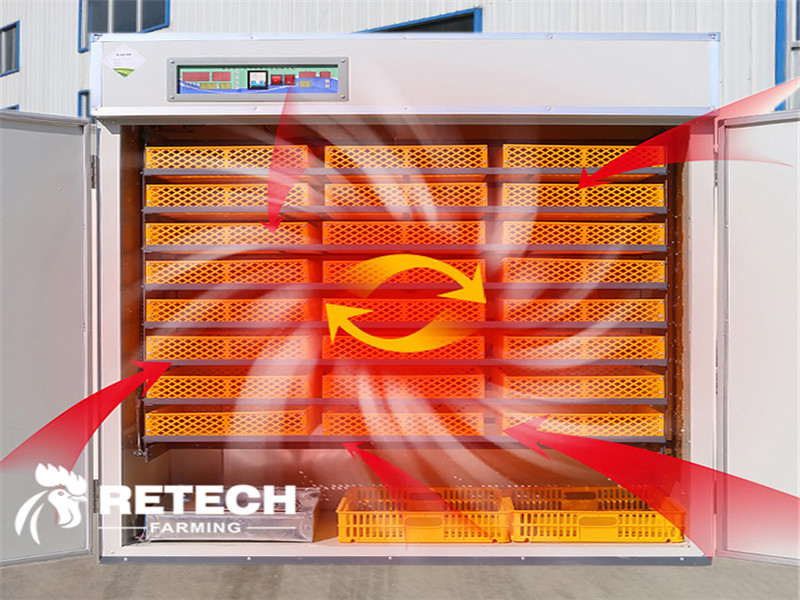

egg incubator 2

Before hatching, if the temperature is high, the embryo develops faster, and the eggs should be aired regularly in the later stage of hatching.

According to the eggs: the purpose of the eggs is to check whether the embryos are normal, so that infertile eggs, dead sperm eggs, stillbirth eggs and broken eggs can be removed in time. During the incubation period, the eggs are generally photographed 2 to 3 times, with the first photo in 5 days, the second photo in 10 to 11 days, and the third photo in 18 days.

Generally, only a part of the second egg inspection can be randomly checked in a chicken farm. In large hatcheries, due to the large workload of egg inspection, only one first inspection is generally performed. In addition to taking regular photos of the eggs according to the work schedule, 20 to 30 eggs are randomly taken out of the incubator every day for inspection, so as to see the fetus and apply temperature.

Ventilation:

The air in the hatching room should be fresh, and the ventilation equipment and conditions should be used to meet the requirements of the air exchange in different periods of embryonic development. When ventilating, attention should be paid to heat preservation, and the temperature should be kept as stable as possible.

Shifting trays:

The eggs are hatched for 18 to 19 days, and the eggs should be moved from the hatching tray of the incubator to the hatching tray.

This process is called tray shifting, also known as tray placement. When moving the plate, the action should be light, steady and fast, and the time of moving the plate should be shortened as much as possible to reduce the broken eggs. The eggs of different varieties or strains should be marked.

Hatching:

When the chick embryos develop normally, the shells will be broken at the time of transfer, and hatching can begin after 20 days. Generally, the chicks are picked once every 4 hours. You can also pick the first time when the hatching is 30% to 40%, the second time when the hatching is 60% to 70%, and finally pick the chick once again.

During hatching, the lights in the device should be turned off to avoid chick disturbance affecting hatching. When picking chicks, the movements should be light and fast, try to keep the temperature and humidity in the incubator as constant as possible, and pick out the empty shells at the same time, so as not to affect the hatching.

Measures in case of power failure: All large and medium-sized hatcheries should provide their own generators. If there are no conditions, you should contact the power supply department during the incubation period to know the power outage time and the length of the outage in advance, so as to take measures, such as preparing the furnace and heating.

When the power goes out, make the indoor temperature reach about 37 ℃ (the upper part of the incubator), open all the doors of the machine, turn the eggs every 1 hour, and pay attention to adjust the temperature at the same time.

laying hens house

It is suggested that no matter which method of incubation is adopted, hatching records should be made in order to sum up experience and continuously improve the hatching effect. The contents of the records include the date of laying eggs, the number of eggs, the source of the eggs, the situation of previous egg shots, the results of incubation, and changes in temperature and humidity during the incubation period.