Laying hens farming equipment in Kenya is popular with modern poultry farm, especially large farms. Layer hens need to be convenient for feeding, egg picking and manure handling. Retech farming’s fully automatic layer cage raising equipment, the egg picking belt can easily receive the eggs in the cage, and transport them through the central conveyor belt, which is convenient for manual picking of eggs.

modern chicken farms

We can use the automatic 9RT-LCH4240 cage equipment for the closed layer chicken house.Automated chicken cages are a trend, popular in tropical countries such as Africa, if you plan to carry out a 20000-100000 poultry project, H-type battery egg cages are the best choice.

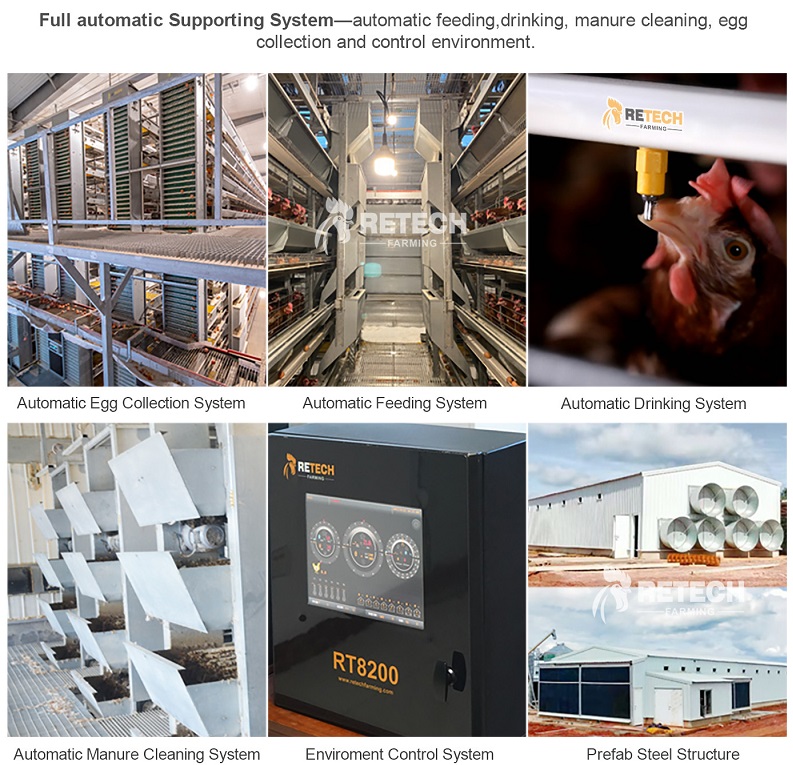

The advantage of the fully automatic H-type laying hen cage is a high degree of automation, equipped with automatic egg collection, feeding, manure cleaning, drinking water, environmental control and other equipment. Make poultry farm more efficient and save labor costs.

Automatic layer battery cage

Get a Free Quote

It is suitable for chicken friends who have large land and want to raise more than 20,000 chickens. In commercial laying hen farming, farmers are more willing to use chicken coops with automatic manure cleaning equipment, which meet local hygiene standards, and a clean breeding environment is better accepted by the market.

Advantages of H-type laying hen cages

Retech farming laying hen equipment is of high quality. We have our own factory, which has passed ISO9001 certification, and cooperates with local universities in Qingdao to research and design, making chicken raising equipment more scientific and durable. The cage net and cage leg support frame are made of Q235 international steel wire, which ensures that the cage net provides enough elasticity for the laying hens, so that the chickens have a good laying feeling.

>Long-lasting quality, hot-dip galvanized material with 15-20 years service life.

> Intensive management and automated control.

> No waste of feed, save feed cost.

> The sufficient drinking guarantee.

> High-density raising,saves land and investment.

> Automatic control of ventilation and temperature.

Complete feeding system

Mobile hopper (cradle feeding) is available. Connection to the silo via a cross-feed screw conveyor. The feeding cart is manually controlled and can feed in multiple periods of time. In this system, the feed is automatically distributed from the feed bin to the feed cart through the auger located in the pipe with a diameter of 90-150 mm, and finally reaches the trough evenly. The automatic feeding system can be adjusted according to the condition of the flock.

modern chicken cage

Fully automatic drinking nipple

The sensitivity of the nipple has been tested many times in the laboratory, and the chicken can drink water with a light peck.

Egg collection system

It consists of an egg collector, an egg belt, and an egg belt hook. The number of layers of the automatic egg collection system varies from 3 to 10 layers. The battery layer cage can also be equipped with an egg conveying system, which can convey all the eggs from different houses to the egg storage room. The egg collection system can greatly reduce the egg breaking rate and reduce the labor force.

egg collection system

Environmental Control System

The automatic poultry environment control system mainly includes fans, wet curtains, small windows, etc. They are used for ventilation and cooling in poultry farm. Keep the house temperature at around 25°C. Provide a good and comfortable growth environment for chickens.

chicken raising system

Fully automatic poultry manure cleaning system

The chicken manure falls from the cage into the manure cleaning belt, and the running of the manure cleaning belt can remove the chicken manure from the rear end of the house.

Automatic battery cage system for 20,000 birds in Kenya

Our Kenyan customer has adopted H-type laying hen farming equipment. From scheme design to project implementation, we have in-depth communication with customers to meet their expectations. The customer’s farm is equipped with automatic feeding, drinking water, egg collection, manure cleaning, and environmental control equipment.

Customers recognized our product and service capabilities, and expressed that they would continue to cooperate with us in subsequent expansion projects.